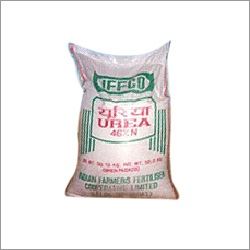

PP HDPE Bag

Price 10 INR/ Bag

MOQ : 10000 Bags

PP HDPE Bag Specification

- Printing

- Flexographic or Rotogravure, Multicolor Printing Available

- Feature

- Moisture Proof, Durable, Eco-Friendly

- Size

- Customized as per requirement

- Buttom Base

- Stitched or Folded Bottom

- Weight

- Lightweight (Varies based on size and requirement)

- Liner

- With or Without Liner

- Color

- Natural, White, Transparent, or As per Requirement

- Lamination

- Available (Optional, Single or Double Side)

- Bag Type

- Woven Bag

- Surface Treatment

- Anti-slip, Matt or Glossy

- Plastic Type

- PP (Polypropylene), HDPE (High Density Polyethylene)

- Product Type

- PP HDPE Bag

- UV Stabilization

- Available upon Request

- Shape

- Rectangular or as per Custom Design

- Terpolymer Coating

- Optional

- Recyclability

- 100% Recyclable

- Capacity

- 5 kg to 100 kg

- Closure Type

- Open, Heat Sealed, or Stitched

- Denier

- 400D to 1200D

- Elongation

- Minimum 15%

- Mesh

- 8 x 8 to 14 x 14

- Tensile Strength

- High tensile strength for enhanced load capacity

- Usage/Application

- Packaging of Grains, Sugar, Cement, Fertilizers, Seeds, Chemicals etc.

- Moisture Barrier

- Yes, with Lamination/Liner

PP HDPE Bag Trade Information

- Minimum Order Quantity

- 10000 Bags

- Supply Ability

- 200 Bags Per Month

- Delivery Time

- 1 Week

About PP HDPE Bag

The PP-HDPE Bag offered are designed from high quality plastic & innovative machinery. They are made in accordance with the present market standards. Apart from this, they are available in variety of colors & sizes. The PP-HDPE Bags are highly recommended due to their perfect stitching. Further they are capacious and can be used for shopping & marketing & many more purposes. They can be availed from us at reasonable prices & are precisely woven by making use of the best grade HDPE materials sourced from trusted vendors.

Versatile Packaging for Industrial Needs

Our PP HDPE Mesh Bags are engineered to handle a wide array of products such as grains, fertilizers, cement, and chemicals. With customizable sizes and shapes, they provide effective packaging solutions for different industries, accommodating varied weight requirements and ensuring reliable performance during storage and transport.

Protection and Sustainability

Built with moisture barrier technology and options for UV stabilization, these bags secure contents from environmental damage. The 100% recyclable material and eco-friendly design support sustainable practices, helping manufacturers reduce their environmental impact without compromising packaging durability.

Custom Features for Enhanced Utility

Customers can select from multiple closure types, liners, and lamination options to meet specific storage and shipping needs. Advanced printing options help with branding, while surface treatments, such as anti-slip finishes, ensure safer handling. Each bag is tailored for optimal strength and elongation, guaranteeing secure and efficient use.

FAQs of PP HDPE Bag:

Q: How are PP HDPE Mesh Bags manufactured for custom size and capacity requirements?

A: PP HDPE Mesh Bags are produced using woven technology, combining polypropylene and high-density polyethylene fibers. The mesh pattern, denier, size, and shape are easily customized during weaving and finishing processes to match your specified weight capacity and packaging dimensions.Q: What types of closure options are available for these bags and how do they benefit usage?

A: You can choose between open, heat-sealed, or stitched closures depending on your application. Heat-sealing and stitching provide secure containment, especially for fine or powdered materials, while open tops facilitate easy filling for bulkier products.Q: When is UV stabilization recommended for PP HDPE Mesh Bags?

A: UV stabilization is suggested when bags are exposed to extended outdoor conditions, protecting the contents and material from degradation caused by sunlight. UV treatments prolong bag usability and preserve packaged goods during storage and transportation.Q: Where can these bags be used for packaging and transport?

A: PP HDPE Mesh Bags are suitable for industrial, agricultural, and commercial sectors. Theyre extensively used in India and worldwide for packaging and moving grains, sugar, fertilizers, cement, seeds, and various chemicals safely and efficiently.Q: What is the process for ordering bags with specific printing and lamination features?

A: Customers can provide detailed requirements like preferred printing technique (flexographic, rotogravure), color, logo, and lamination needs. Manufacturers adjust the production process to incorporate multicolor prints and single or double-sided laminations, tailoring bags for brand identity and additional protection.Q: How does using these bags benefit manufacturers and suppliers?

A: PP HDPE Mesh Bags offer high load capacity due to their tensile strength, moisture-proof properties for sensitive goods, and full recyclability. Their lightweight yet durable build reduces shipping costs and environmental footprint, all while providing secure and attractive packaging options.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PP-HDPE Bags Category

Printed HDPE Bag

Price 10 INR / Bag

Minimum Order Quantity : 10000 Bags

Size : 14 ,15 ,22 , 24 ,26 , 27 , 28 ,30 , 32 , 36 , 40 tube ,open ,s/c ,c/c

Weight : 3 gram, 3.5 gram , 4 gram ,4.5 gram Grams (g)

Color : available in all colour

Plastic Type : HDPE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free